Gallery

View Our Image Gallery

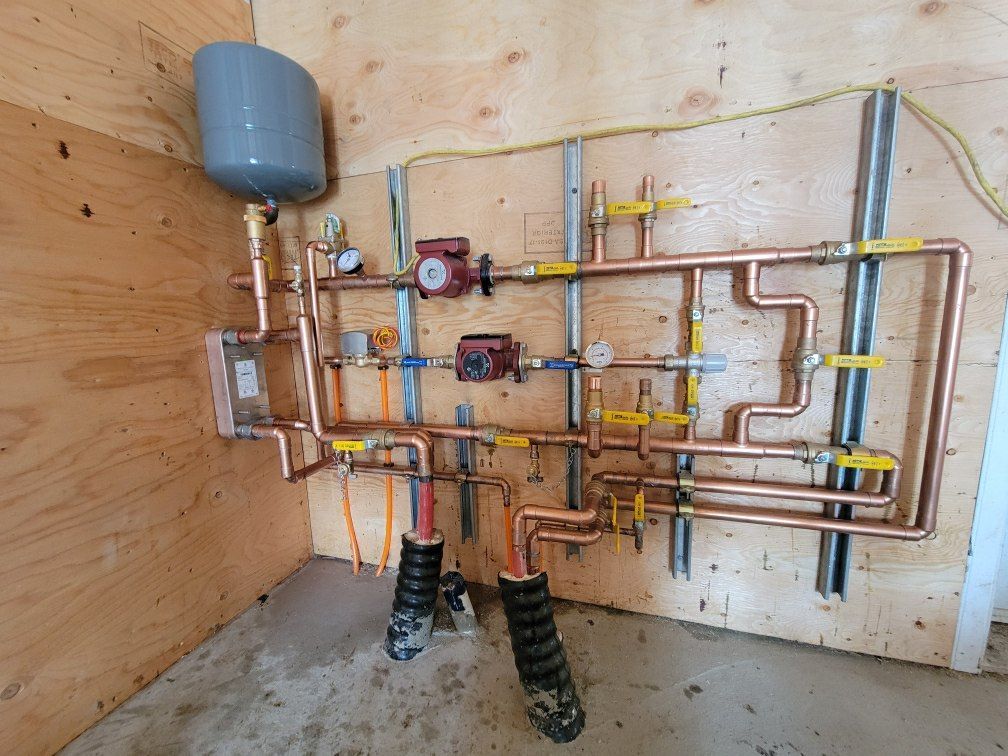

At ACS Mechanical Inc, we have been providing quality heating products and services in Whitehorse and the Yukon territory for over 20 years. We install a variety of heating systems, including hydronic, biomass boilers, wood oil and electric units, and more. Check out the gallery to see the quality and craftsmanship of our skilled personnel.

For all your heating needs, call or email us

NEWS ARTICLES

-

Biomass Energy has Advanced By 40 Years

By Chuck Tobin on October 26, 2018

Bewilderment may not be the wrong word to describe the feeling of those in the know who don’t understand why the Yukon isn’t jumping head-first into biomass energy – energy from wood chips and other similar wood products.

They just don’t get it.

Bewilderment might not be the right word, but it’s not far off.

David Dubois of Fink Machine Inc., a company which supplies biomass boilers, emphasizes Sweden provides 40 per cent of its heat and electricity with some form of biomass, 40 per cent for a country of 10 million people.

Dubois was among the handful of supporters at Thursday’s demonstration of a working Hargassner biomass unit imported from Austria by Chris Schmidt of ACS Mechanical.

Raven has been saving about $25,000 annually in heating fuel while displacing tonnes of green house gas emissions by burning mostly discarded wooden freight pallets.

Schmidt says he’s known about the potential of biomass for some 40 years, since the days as a young lad in Germany, when he and his dad were messing with the technology. It was a little bit hit-and-miss back then.

But there have been 40 years of advancement, Schmidt points out.

He says the community of Teslin has fostered a shining example of how wood chips can provide district heating and employment. (See separate story, this page.)

Biomass energy displaces greenhouse gas emissions and keeps the money local, instead of paying to have heating fuel hauled up the highway.

Schmidt says he’s been pushing the idea of biomass for 20 years, since his days living in Ross River when he remembers trees cut down as part of a fire smart program were burned. That wood could have been recovered and used for energy, he said. (See Teslin story.)

One of his colleagues in the push to adopt biomass has estimated if Whitehorse was fire smarted to the degree recommended, wood recovered could provide 40 years of energy for the city.

Schmidt figures his biomass unit on display in the empty lot next door to Lumel Studios could probably heat 10 Whistle Bend homes, given the energy efficiency standards required of new houses in Whitehorse. (See Teslin story.)

Schmidt, Dubois, others who know biomass, who understand the potential, just don’t get why the Yukon hasn’t taken a bigger bite of such an obvious opportunity just sitting there. It’s a no-brainer, as one fellow put it. (See Teslin story.)

Dubois points out greenhouse gas emissions from a biomass unit are some 90 per cent lower than a diesel-fired unit.

Some $60 million or $70 million to purchase home heating fuel leaves the Yukon every year, according to statistics.

Dubois says there are literally hundreds of thousands of biomass units in use in Europe right now.

But the number of biomass units in the Yukon – outside of Teslin – can almost be counted on one hand.

They just don’t get it.

-

State-of-the-Art Boiler Now Heats Raven Recycling Centre

By Chuck Tobin on March 15, 2016

On the eve of a two-day forum about using biomass to create energy, the territorial government and Yukon Research Centre unveiled a new heating system for the Raven Recycling Centre.

The state-of-the-art wood-fired boiler purchased from Austria has been operational for five days, burning waste wood pulverized by a drum grinder, nails and all.

Stephen Mooney of the research centre’s Cold Climate Innovation department said he sees the project as a solid steppingstone to expand the use of wood chips in the Yukon to generate heat and electricity.

Is it possible to provide district heating to a small Yukon community?

“Absolutely,” said Mooney.

He recalled his visit to a small village in Finland which is powered by wood gasification units that produce both fuel to burn for heat and fuel to drive turbines for generating electricity.

The heating and electricity requirements for one 32-unit condo development is provided by one wood gasifier that is 1.5 metres wide, three metres long and 2.5 metres high, not including the storage silo for the wood chips.

Mooney said using wood chips provides the ability to automatically feed the fire using a mechanical auger system, as opposed to having a boiler burning cord wood that has to be reloaded regularly by hand.

Going with wood chips over pellets was on the advice coming out of the Northwest Territories, where there’s been a noticeable move in the Yellowknife area from more costly heating fuel to imported wood pellets, he said.

Mooney said the reason the N.W.T. imports wood pellets is because it doesn’t have any trees, and pellets are less bulky than chips.

But the advice is if the Yukon has trees – and there are plenty of them – go with wood chips because they can provide a local fuel source, he said.

Mooney said Chris Schmidt of ACS Mechanical initiated the Raven Recycling project when he approached the Cold Climate Innovation department with his proposal.

Raven was able to move the project forward through $60,000 in joint funding from Cold Climate Innovation, the Yukon Energy Solutions Centre and the federal government.

Mooney said most of the waste wood was provided by pallets already stockpiled by Raven and pulverized by the drum grinder Castle Rock Enterprises uses to deal with waste wood at community land fills, he said.

The appliance can handle nails because the nails are simply pushed through to the ash box, though they still need to look at maximizing a method to remove more nails using some sort of magnet, he said.

The two-day conference that opened this morning is focused on looking at what’s happening in the world of biomass and what lies ahead; what the potential may be to expand viable opportunities here in the generation of heat and electricity.

The audience, for instance, heard this morning from the Kluane First Nation and how it was chipping its own wood to supply a boiler that provided district heat to four of its government buildings, though the heating system is now burning logs.

The First Nation is looking to expand its use of district heating and is also considering the use of wood biomass to generate electricity, the audience heard.

Colin Asseltine, general manager of the Kluane Community Development Corp., told the audience maximizing the use of wood is a no-brainer, given the vast areas of forest killed by the spruce beetle infestation through the 1990s, and a more recent forest fire.

An analysis of the availability of fuel wood showed a sustainable annual harvest of 100,000 cubic metres (27,600 cords), Asseltine told the audience.

More presentations were scheduled today and Wednesday to discuss biomass initiatives and opportunities in the Yukon.

The man behind the Raven Recycling project is scheduled to make a presentation, as is a representative of a local plumbing and heating company, who is scheduled to talk about domestic wood stoves.

The forum is being sponsored by the Yukon Research Centre and the federal government.

-

Raven Bets on Biomass

By Ashley Joannou on March 16, 2016

The backyard of Whitehorse's Raven Recycling is home to the territory's latest European transplant. The recycling depot has swapped out its old boiler for one originally developed in Austria.

The backyard of Whitehorse’s Raven Recycling is home to the territory’s latest European transplant.

The recycling depot has swapped out its old boiler for one originally developed in Austria. The fire engine-red contraption in the backyard lives on a steady diet of old wood pallets, which it uses to create heat.

It’s the latest pilot project, funded in part by Yukon College’s cold climate innovation branch, attempting to bring more biomass heating to the Yukon.

“We’ve got a lot of biomass,” says director Stephen Mooney.

“I can take you places 10 minutes from this spot and show you huge mounds of trees just rotting that could be chipped up this summer and stockpiled for biomass units.”

It took two hours in December to grind about 300 pallets into 21 tons of wood chunks. That’s hopefully enough for the Hargassner woodchip boiler to heat the warehouse and offices for about a year.

“Which is not actually that many,” says Raven Recycling’s Danny Lewis. “We have about a third of that piled up already since we finished chipping.”

What’s left after grinding has no consistent shape or size. It looks more like a family of angry beavers went to town shredding any wood in their path.

A magnet is run through the pile to help yank out any stray nails and the shards of wood are dumped into a room adjacent to the boiler.

If everything goes as planned, that’s the last time a person needs to touch the wood.

Metal arms spin in the adjacent room pulling the wood crumbs towards what is essentially a giant corkscrew. That carries the wood to its last destination, to be burned in the boiler.

“In the world of wood chips, these are ugly chips,” Mooney says as he reaches towards the slowly spinning screw and pulls out different sized chunks.

“These aren’t pretty chips. But that’s the reason this boiler is here, this boiler can take ugly chips.”

The project will track the type of wood that’s used, its moisture levels and the amount of heat created. It’s all in an effort to prove these contraptions are viable options for the North and to discover what wood chips work best.

The system is powered by gasification. That means that heated wood, when mixed with the right amount of oxygen, vapourizes to become synthetic gas.

A computer controls the flow of wood and air into the burner, since different types of wood need different amounts of oxygen to burn most efficiently.

The project is the brainchild of Chris Schmidt, who has spent 33 years working as a technician installing boilers.

Originally from Europe where boilers like this are much more commonplace, Schmidt said he spent years looking for a way to bring a project home to the Yukon.

It was only two or three years ago that this style of boiler was approved by the Canadian Standards Agency.

There are about 12 to 14 similar units in Canada right now, Schmidt says. He was trained on one in Quebec.

The cost of cutting, crushing and burning wood is much more consistent than oil prices. Wood is also found much closer to home.

“There’s a lot of biomass to use, which also keeps the jobs here, because somebody has to cut it, somebody has to shred it, somebody has to move it, somebody has to monitor it,” he says.

Schmidt says the biggest obstacle to convince people to consider using a boiler like this is the high up-front costs. Just the boiler itself cost $55,000 and thousands more to install, he says.

Lewis says Raven’s fuel bill has been anywhere from $30,000 to $40,000 a year. Now they anticipate about $3,000 to $5,000 a year in labour costs to help gather and process wood to feed the boiler.

“What I’m hoping is that people will get aware of it and consider it as an option to heat buildings,” Schmidt says.

The Yukon government released its biomass strategy earlier this year. As part of that strategy the government has agreed to consider using biomass whenever it plans a new building or a retrofit of an old one.

A government spokesperson says officials are looking at a handful of projects that could use biomass, but no decisions have been made yet.

Approximately 13,000 cords of wood are harvested annually in Yukon, mostly from beetle-kill wood in the Haines Junction area, to heat homes and buildings. That’s about 17 per cent of Yukon’s total consumption of energy for heat, according to the government.

Schmidt envisions a time when these kinds of boilers exist in all of Yukon’s communities as a way to give new life to waste wood.

Mooney says he’d eventually like to look into systems that not only provide heat, but also electricity. The ones he’s considering haven’t been approved in Canada yet.

If that does happen, Yukon College has a hole in its basement that might be a good fit.

When the new campus was built in 1988 it came with a giant gasifier. It was billed as a furnace that could eat almost anything, from scrap wood to garbage, but it never really worked right.

The technology was new. The machine’s serial number was 001, Mooney says.

He says the feedstock was never consistent and someone had to be there at all times to make sure things kept running.

“It could have been a good thing, but it wasn’t given the due diligence that it needed.”

When Mooney started his job five years ago, a report claimed the machine could be fixed, but would cost “millions,” he says.

It wasn’t worth the money and the system was pulled out.

But the industry has grown since then. Now there are about 70,000 of these kinds of systems across the globe, according to Schmidt.